Production

UP-TO-DATE PRODUCTION FACILITIES

Over 300 tons of milk are processed by the Company's factory per day! Main Company's product is the ice cream, which daily output is near 150 tons.

Such performance has been achieved due to high-capacity and exclusive to Ukraine equipment:

- TetraPak Straightline SL1100 F2 is able to produce over 27,000 pieces of ice cream per hour and 600,000 pieces per day, accordingly. This is the first line in countries of the Eastern Europe having such an ice cream production capacity.

- Temperature of -30ºC at the output of the quenching freezer provides for better appearance and quality of ice cream when it is packed and stored thereupon.

- The up-to-date equipment of the German manufacturer Big Drum enables the Ukrainian consumers to be offered the exclusive ice cream by the Company.

EUROPEAN APPROACH

In September 2014 the Company was successfully inspected by the EU Mission for the Ukrainian Dairy Product Quality Standards. The Company became the sole Ukrainian ice cream producer that has got a license for supply of products to the EU countries upon results of the Commission audit..

Recognized RUD TM brand "The 100% Ice Cream" was certified through labeling with "Dobryi Znak" mark upon quality control in seven independent European labs, thus confirming its compliance with both Ukrainian and European quality and safety requirements..

The Company's adherence to the European approach to the product quality has been proven by the instance of "The Esquimau-Organic" – the first organic ice cream whenever available in Ukraine and entire region of the former USSR. This is approved product having the Organic Standard UA-BIO-108 Certificate, whereby it is made in compliance with all requirements of the EU Regulation on organic farming & production.

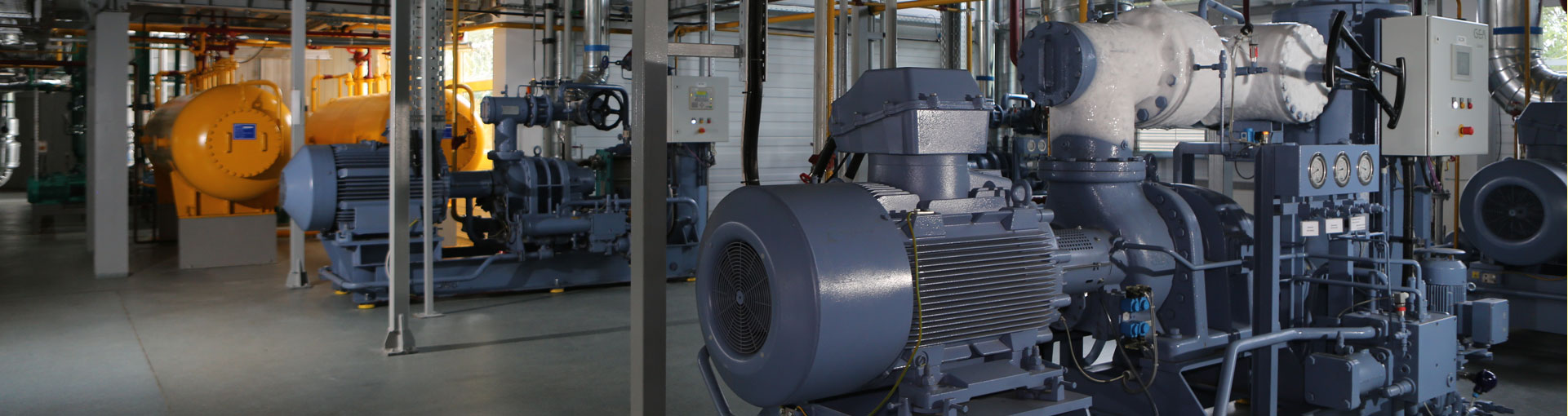

RESPONSIBLE RESOURCE CONSUMPTION

With reference to scale of operations, the Company is sensible of responsibility for the environmental impact thereof. Energy efficiency is of the most important field of concern of the environmental management system:

- Subsequent to the energy audit of the factory and implementation of new technologies we have managed to increase the efficiency of power generating plant up to 94%;

- Following introduction of heat recovery system and frequency control over power consumption by equipment, we have decreased electric power consumption of the new refrigerating ammonia compressor by 20%.

Quality control and compliance with standards

The Company is in possession of the own in-situ resources and puts an emphasis on quality of the raw materials delivered for processing. The Company exercises maximum quality control at both milk procurement and production phase.

The management system of the Company is the same as implemented in the leading international companies:

QUALITY MANAGEMENT SYSTEM ISO 9001:2001;

ENVIRONMENTAL MANAGEMENT SYSTEM:

ISO 14000:2004;

FOOD SAFETY MANAGEMENT SYSTEM: ISO 22000:2005;

MANAGEMENT OF FACTORS AFFECTING PRODUCT SAFETY: HACCP (Hazard Analysis and Critical Control Points).

The Company is qualified for compliance with GFSI (Global Food Safety Initiative) global standards. The GFSI mission is permanent worldwide improvement of the product safety management system.

Due to implementation of the most advanced technologies and European approach to business, the Company has been steadily maintaining leadership in the Ukrainian market.